What is Plastic Fiber Optic? Application of Plastic Optical Fiber

What is Plastic Fiber Optic? Application of Plastic Optical Fiber

Blog Article

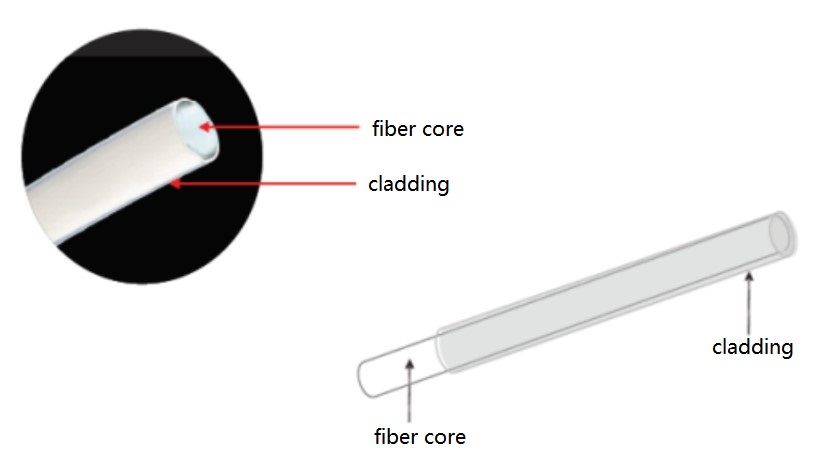

There are many principles and types of optical fibers, and the materials used for decoration and lighting are usually plastic-coated optical fibers. What is plastic fiber optic? Plastic optical fiber are commonly known as plastic optical fibers (POF). They are made of special core materials and cladding layers. They can make the optical fiber soft. The core materials are mainly organic glass (PMMA), polystyrene (PS) and polycarbonate (PC), and the cladding layer is fluoroplastic. Due to the softness of plastic fiber optic, splicing is simple. They are also easy to bend and easy to construct.

Characteristics of Plastic Optical Fiber

- High flexibility, easy to cut, not easy to deform;

- Plastic optical fiber has good end-face luminescence and full-body luminescence effects. Uniform light guide and high brightness;

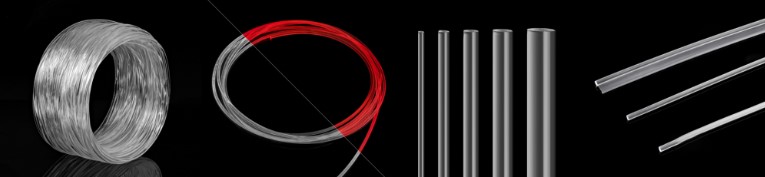

- Wide range of wire diameter: 0.5mm~30mm;

- The appearance color is changeable, usually fully transparent or milky white;

- The shape of plastic fiber optic wire is changeable. Different appearances can be developed according to specific requirements;

- Stable performance and strong anti-aging ability;

- Because it is extruded, the extruded cross-section can be stretched into different shapes according to the design. Which can meet both the appearance and the structural assembly requirements.

The Production Process of Plastic Optical Fiber

Infusion optical fiber

The earliest flexible POF is the infusion process. First, the fluoroplastic tube of the POF outer layer is processed. And then the acrylic monomer mixture is infused into the tube. It is polymerized by high temperature heating for about 10 hours and then cooled. It is similar to the way of filling sausages. Disadvantages: The wire diameter error is large, reaching ±0.3mm. The core and cladding are delaminated. Which is greatly affected by the ambient temperature. Low production efficiency and high defect rate.

Extruded optical fiber

The prepared core material and specific fluoroplastic are extruded through two special extruders successively. And finally cooled and shaped to form POF. Advantages: The wire diameter accuracy can reach ±0.05mm. High production efficiency and continuous production. After the material is hot-melted, it can reach a relatively stable state.

Plastic Fiber Optic Product Performance

Plastic optical fiber can be used at -40 to 105℃. Its optical fiber diameter is between 0.5 and 30mm. It can be customized according to the design form. High transmittance core material, good light guide uniformity. Soft light, no glare, no light pollution. When the optical fiber emits light, it is not charged, not conductive. And does not generate heat, so it is safe to use. Good weather resistance, no breakage at low temperature, and maintains softness. At high temperature, maintain a high side light illumination. Good softness, easy to bend and shape. Anti-vibration and impact resistance, easy to install.

The optical fiber does not contain any harmful substances. Such as heavy metals, and complies with the limit requirements of the EU RoHS Directive 2011/65/EU Appendix II Amendment Directive (EU) 2015/863. It has passed the IEC60695-11-5:2004 standard (needle flame) and IEC60695-2-10:2000 standard (glow wire) tests and has flame retardant properties.

Application of Plastic Optical Fiber

Optical fiber side-emitting light strip

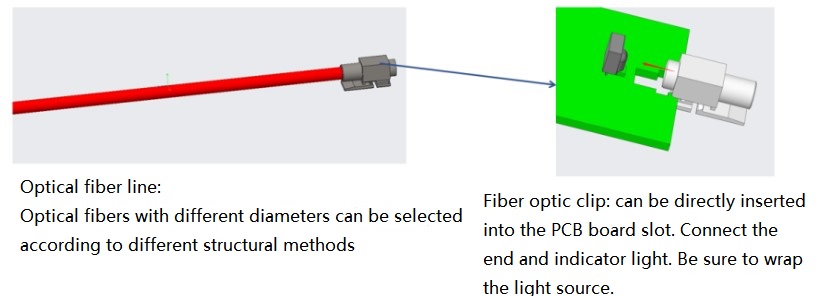

The structure of the optical side-emitting component is composed of two parts. LED light source, optical fiber line and optical fiber structure buckle. The optical fiber line is extruded. Different cross-section structure schemes can be used to fix it during structural design. The upper and lower shells use U-shaped grooves to clamp the luminous optical fiber. The U-shaped groove design must form a track to prevent assembly displacement.

Optical fiber bundle

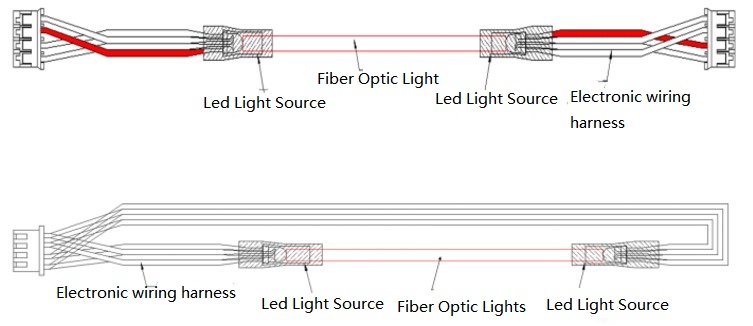

The structure of the optical fiber light strip is composed of three parts: LED light source, optical fiber line and electronic wiring harness. The optical fiber line is directly wrapped and formed with the wire, without the need for special structural design.

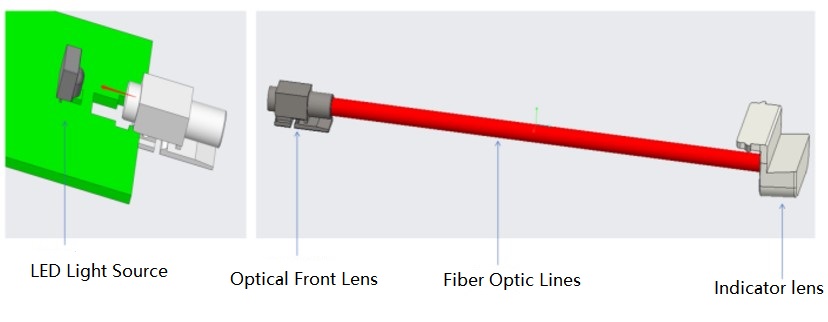

Optical fiber light guide indicator

The structure of the optical fiber indicator is composed of four parts. LED light source, optical front mirror, optical fiber line and indicator lens.

When designing, it is necessary to pay attention to the light shielding property. And the LED light source should be within 0.5mm from the light guide to prevent light loss and insufficient brightness.

Other applications

In addition, plastic optical fiber is also commonly used in home and office smart networks, automotive applications. Consumer electronics and sensors, industrial control bus systems, etc. Report this page